How to create a template for a glass processor

Share this blog:

Templates are essential when working with glass processors. Get the facts you need from industry experts.

When working with a glass processor, it's not just the glass that should be crystal clear. Good communication is essential to ensure you get the glass products you want to the specification you want.

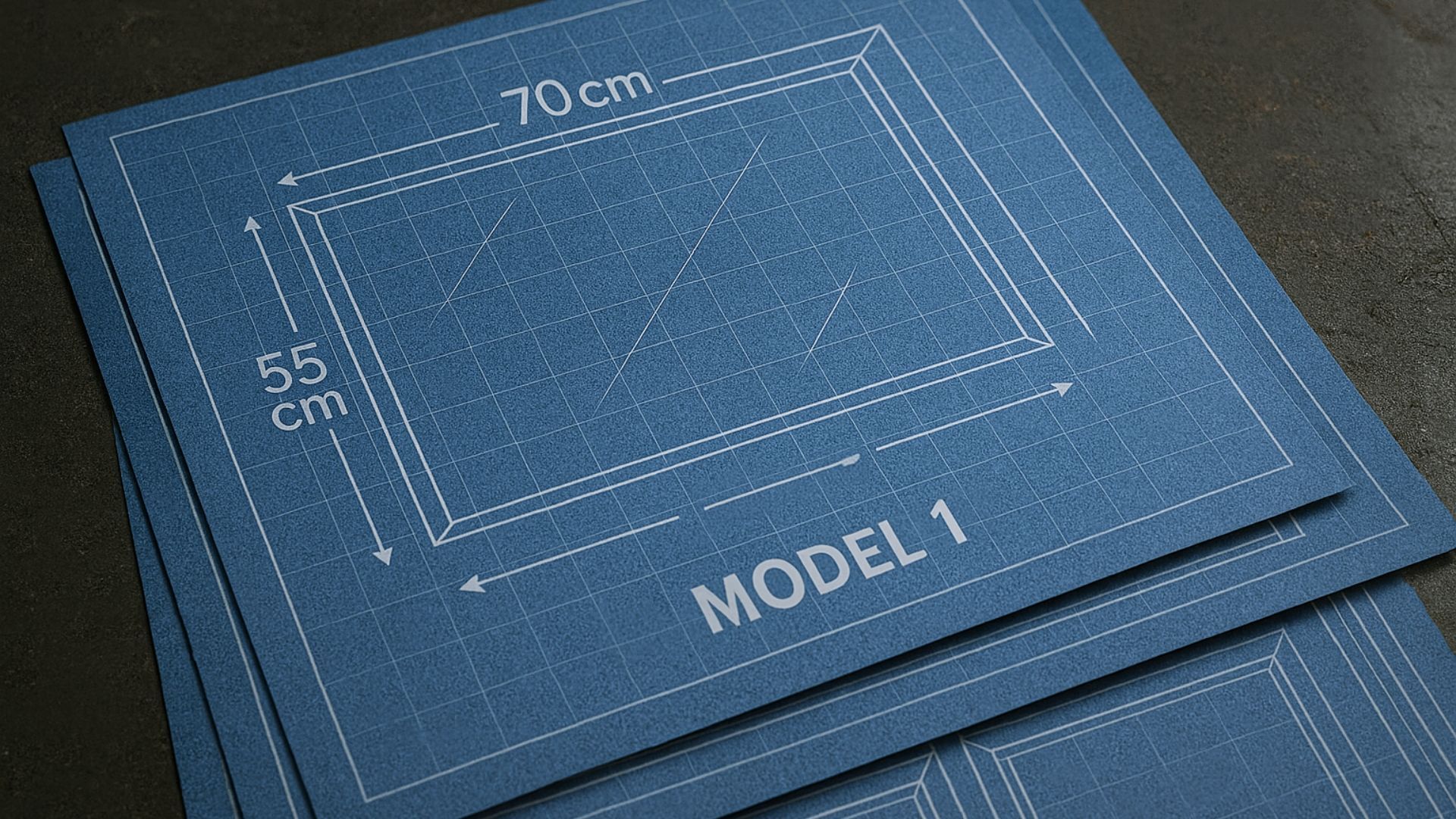

This partly hinges on the template or templates you send to the processor. These are the blueprints of your project. The better they are, the greater your chances of customer satisfaction.

Detailed, accurate templates allow the processor to hit the ground running and not waste any time on clarificatory back-and-forths. It's not just that this is a nuisance. It will also impact your lead times and potentially introduce delays to your project.

Above all, your glass processor needs good measurements. They also need the template to be well-presented. But what do we mean by "good" or "well-presented" in this context?

The importance of accurate measurements

A picture of your design isn't enough. Every line needs to be measured.

And when we say "measured", we're talking accurate measurements – no guesswork. You should label side lengths, heights, thicknesses, block sizes, offsides and

tolerances. You should also mark any cutouts, notches or hardware onto your template.

If your finished design will be installed into a space, it can help to provide a picture or sketch of the space. This could apply if you're going to a glass processor to get glass for a window, say, or a shower enclosure.

Drawings and designs are fine – so long as they're accurately labelled. But it can be to your advantage to provide a template in the shape of the finished product.

What makes a good template?

A template must be the exact size and shape of the finished product. It can be drawn on hardboard, Correx, ply, polycarbonate, sheet metal, hardboard, heavy paper or cardboard – any material, in short, that's thick and won't rip. This means wrapping paper, cloth, thin cardboard and newspaper are all no-nos.

The design should be drawn or printed onto the template with thin, clear lines. Each line and detail must be labelled with measurements.

If your template is made of wood, make sure there are no screws or other bits of hardware sticking out of the surface.

Exactness is all. Many processors will reject a design that uses guesstimates or labels of the "add 2 mm here" variety.

It can also be helpful to mark your template with your company name and project name.

Finally, be mindful if your design has different surfaces. If one side is frosted or made of

mirror glass, you should mark the relevant side.

Physical templates are best for simple shapes. They can be made by overlaying your material onto the space where the glass will sit. You can then trace and cut the shape.

Whatever material you use, your template will be digitised by the glass processor and fed into a computer numerical control (CNC) machine or other type of glass cutter.

If the design is more complex, computer-aided design (CAD) files are the way to go.

CAD files

Most glass processors use CAD and cut glass using a CNC machine or CAD-driven laser cutter.

This involves feeding a DXF file into the machine. The machine then cuts the glass using the file as a guideline.

DXF – an acronym that stands for "Drawing eXchange Format" – is a widely used file format for sharing and exchanging CAD data. It was created to be used across different software programs.

DXF files are vector-based. This means they represent a design with lines, curves and other geometric shapes rather than individual pixels.

More and more glass processors ask customers for DXF files. If you don't have the software or skills, this can be a time-consuming job.

Some companies process DXF files for you. You submit a template on hardwood or another suitable material and they turn it into CAD files.

Files can be shared with the processor via a file-sharing platform, email, cloud storage or a dedicated customer portal. Some processors may also accept memory sticks or other physical storage devices.

Before sending files, make sure you've got the right format. DXF is widely used – however, older versions of software may struggle with newer formats and vice versa.

Making a physical template for curved glass

If you're ordering a piece of curved glass, this needs to be reflected in your physical template.

You should use a material like hardboard, fibreglass or Aqua Plus PVC. The template should be reinforced to make sure it's stiff and sturdy.

Check the accuracy of the template by inserting it into the frame where the finished product will be installed. Make sure the centre is smooth and free from bowing and warping. Any imperfections of this kind will affect the manufacturing process.

What are tolerances?

When sharing measurements with a glass processor, you should include tolerances. This is a technical way of saying "wiggle room" – the minimum or maximum variations that can be allowed.

Glass processors can be exact but may not be able to cut a piece of glass to the exact millimetre or less. Tolerances let them know how much variation is acceptable.

Your glass processor should ask for tolerances at the start of the process. It's important to provide tolerances so the processor can give you an accurate quote – and so you get a usable product at the end.

It's a great example of how important clear communication is when working with a glass processor. Give them the details you need and you'll get the product you want. Skimp on the details and you'll be looking at longer lead times – and, at worst, having to start the process all over again.

Founded in 1993, ToughGlaze is one of the UK's leading

toughened glass suppliers. We work with leading construction, architecture and manufacturing firms to deliver high-quality, fully compliant glass products – on time and on spec. Want to talk glass?

Get in touch today for a fast, free quote.